- CALL: +92 21 3505 4449

- EMAIL: [email protected]

Industrial Plants

We deal in

- Flour Mills

- Soap Plants

- Pasta Plants

- Dies for Pasta Plant

- Processing Machines & Packaging Production Lines

- Food Processing Systems

- Alapala, Turkey

- Binacchi & Co, Italy

- Fava S.p.A, Italy

- Fen Italia, Italy

- Landucci, Italy

- Sovimp s.r.l, Italy

FLOUR MILLS

Alapala supplies its worldwide customers with state-of-the-art flour milling technologies and innovative research and development approaches for flour milling machinery and turnkey flour mill plants. As Alapala, we have been offering wide range from complete turnkey flour mill solutions to specialized machines for every step.

SOAP PLANTS

TBinacchi has more than 30 years of experience in manufacturing soap and glycerine plants. This means that we can provide you the most modern solutions that have been already fully tested, thus ensuring lower project costs and less problems. With Binacchi you select a trustworthy partner, able to be at your side for many years.

Binacchi sells solutions and not simply plants: we are able to satisfy your requests with professionality, customizing well proven technologies to your needs.

There are two main processes to obtain soap: one is using oils and fats as raw materials and the other utilizes fatty acids. The selection of the most suitable solution depends on many technical and economic factors and should be done together with Binacchi.

PASTA PLANTS

Specialty pasta lines Capacities up to 2000 kg/h – Production of round nests, oval nests, lasagna and large short goods shapes

Thanks to our patented process technologies, developed and perfected over 80 years of activity, you can optimize each and every raw material to obtain a product of the highest quality. The operational flexibility and simplicity of our lines have always been our strength. We also provide support to our customers with unmatched commitment through dedicated after-sales assistance, training courses and a research and development laboratory for studying and developing new products.

FOOD PROCESSING LINES

FEN manufactures machineries and industrial plants for the production of snack pellets and, more in general, of extrusion-based food. Thanks to the active cooperation with ISMEC group, FEN has been able to combine the high quality standards of its products to very competitive prices.

We are always striving to develop new technologies. Our aim is to bring innovation into the production processes, exploiting our technical and technological know-how and the feedback that we gain from our customers.

DIES FOR PASTA PLANT

Bow-Tie Stamping Machine pasta Bologna Velo of innovative conception, with ver- tical sheet insertion. This characteristic allows to have very short sheet runs between the calibration zone and the shearing zone with enormous advantages on the color of the finished product. The sheet conveyor belt is regulated by an Inverter in order to optimize the speed of the sheet according to the extrusion speed. The machine reaches an high productivity thanks to the perfect balance of the masses.

The short distance of the sheet through its inner part guarantees always the right stability. The computerized system of 10 control allows the optimization of the scrap independently from the speed of the machine and the memorization of the recipes shape by shape.

The possibility of setting up the desired quantity of dry pasta that we wish to produce and the report of all the production data and anomalies on a printer constitute a useful complement for those pasta plants that expect to verify the production around the clock(optional).

The PLC allows to examine at distance, from the Landucci assistance site, the complete status of the machine and the eventual upgrading of the Software. This to notice in real time the arising of any problems thus limiting any production stoppa- ge of the machine (optional). The dimensions are contained to allow the achie- vement of harmonius layouts.

PROCESSING MACHINES & PACKAGING PRODUCTION LINES

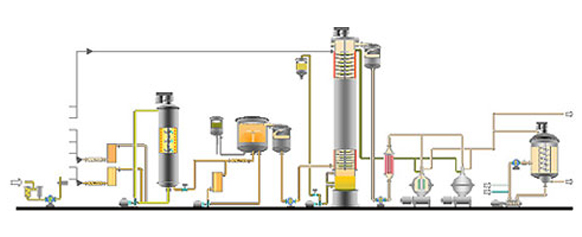

SOVIMP S.r.l. is an engineering and contracting company specialized in the realization of process engineering and in the supply of special equipment, packages and process plant, acting also as main contractor of turn-key realizations, for the chemical, the chemical-textile, the pharmaceutical and the agro-food industry.

SOVIMP has been established in 1994 as aggregation of professionals having operating experience in the design, the construction and the management of process plants in the chemical, the chemical-textile, the pharmaceutical fields as well as in the agro-food one, thanks mainly to the contribution of experience brought in by the personnel recently broken off from a primary international main contractor active in such field.

The continuous horizontal product flow subsequent to filling allows for packaging a multitude of pharmaceutical products different in size and shape

The main activity of the company is then to offer to producers and new investors, an experience matured on the field in primary companies by qualified specialists, to solve the most diversified technical problems that a production plant has in all its phases, from the project ideation to the design and the construction, from the plant management to its revitalization.

The main characteristics of SOVIMP is its global approach to the study of the industrial projects: its activity is then based on the concept that the industrial projects require the optimization not only of each single component but also, and in particular the optimization of the entire process: from the raw material supply to its processing, to the distribution of the finished product to the market.

Then, SOVIMP is ready to face projects requiring both vertical and transversal integration and it can deal with all the aspects regarding process, logistics, economics, finance, operation, marketing ,....

What above is based mainly on a solid knowledge of process engineering, on the availability of the know-how of many production processes, some of them developed internally , and on the capacity to manage complex systems.

Close and long-lasting relationships with primary national and international operators guarantee the access to the most up-to-date technologies and process developments which really represent the state of the art and, moreover, to the final product markets.

Moreover, SOVIMP can rely on a deep knowledge of the market of the manufacturers, which are selected to obtain the best cost/performance ratio, to the final benefit of the Project and of the Customer: Not the single machine but its integration in a complete system is privileged, taking into consideration at the same time not only the technical aspects but also the financial, marketing and management aspects.

Why choose us?

Over a period of time Plastipack developed expertise in providing customized solutions according to customer requirements with experienced technical team, spare parts & after sales service.

- Project Consultation

- Material

- Spare Parts

- Contract Packaging

- After sale service

- Warehousing